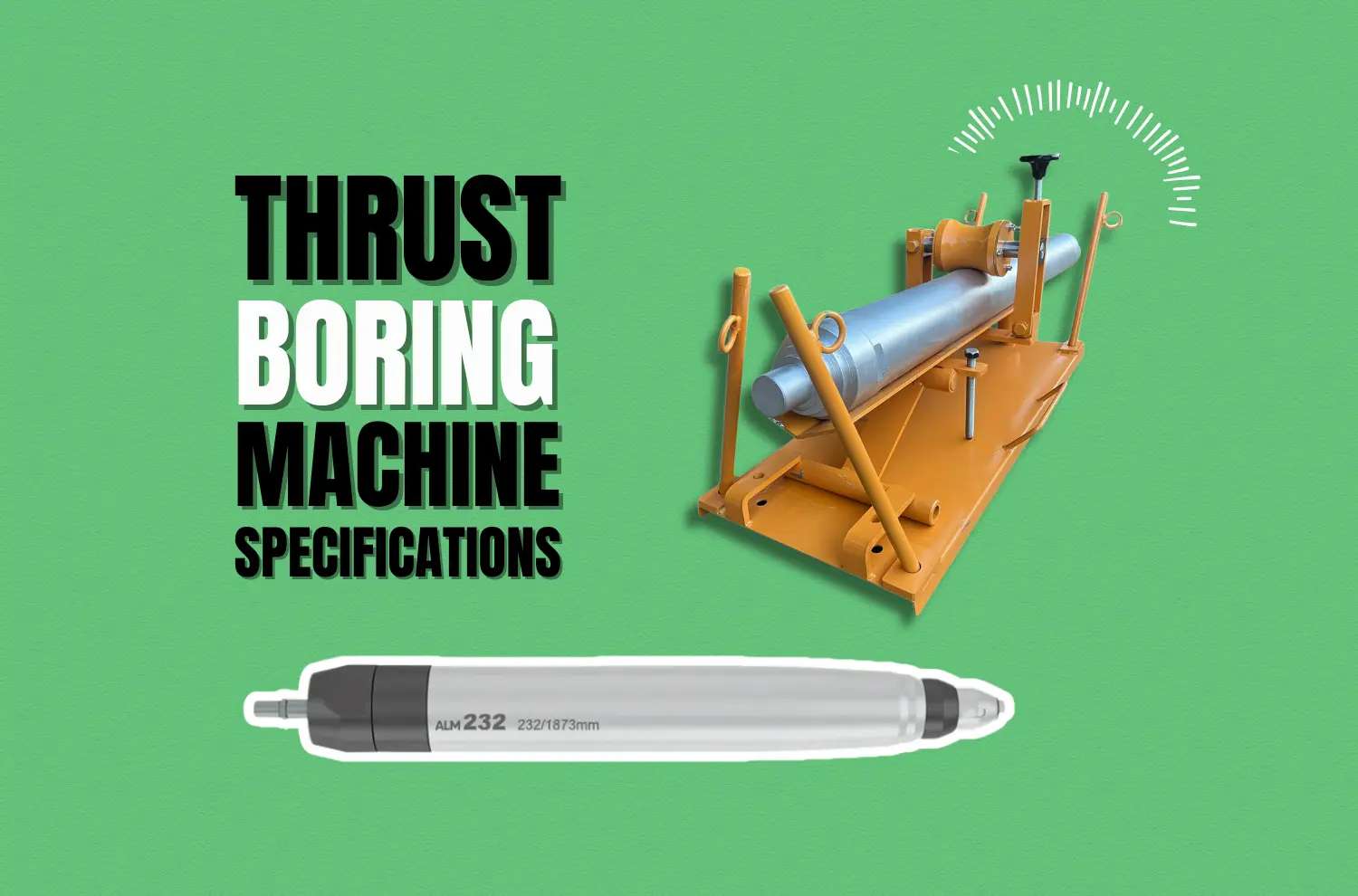

When choosing a trenchless drilling tool, thrust boring machine specifications matter the most. They tell you what the machine can handle, how it performs, and if it fits your project. In this post, we’ll break down the main specs in simple terms so you know what to look for.

Why Specifications Are Important

Every job site is different. Soil can be soft, sandy, or rocky. Pipe sizes vary too. If the thrust boring machine doesn’t match these needs, you waste time and money. That’s why checking key specifications before buying or renting is critical.

Diameter and Length

The body diameter sets the size of the tunnel it makes. Smaller diameters are great for fiber optic lines or water pipes. Larger diameters work for gas lines and bigger conduits.

Length also matters. A longer body can stay steady underground, giving you a straighter path.

Weight and Portability

Weight affects how easy the machine is to move and launch. Lighter models are simple for two workers to handle. Heavier units bring more power but may need extra gear to set up.

Air Pressure and Power

Air-powered thrust boring machines depend on the compressor. Maximum air pressure, usually listed in bars, shows how strong each stroke is. A machine with higher pressure can push through tougher soils. Always match the compressor output with the machine’s requirement.

Air Consumption

This tells you how much air the machine uses. It’s often given in PSI, CFM, or cubic meters per minute. Low air use means you can run longer without draining the system. High use means you need a larger compressor, but you get more force.

Durability and Build

Specs don’t just list numbers. Materials also matter. High-grade steel and solid pistons mean the machine can last for years. A strong build reduces downtime and lowers repair costs.

Matching Specs to the Job

There’s no one-size-fits-all. For small city projects, a compact 50 mm or 75 mm unit is enough. For longer rural crossings, you may need a bigger, heavier model with higher air flow. Always match thrust boring machine specifications with the ground type, pipe size, and project length.

Choosing the right machine starts with reading the specs. Diameter, length, weight, air pressure, and air use all tell you how it will perform. By understanding these numbers, contractors can work faster, cut costs, and avoid damage to the surface.