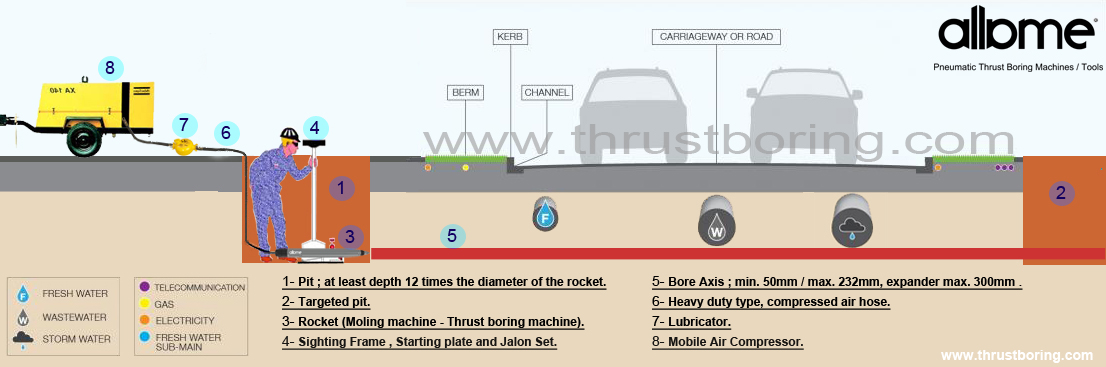

Start-Up, Depth, And Target Determination Running

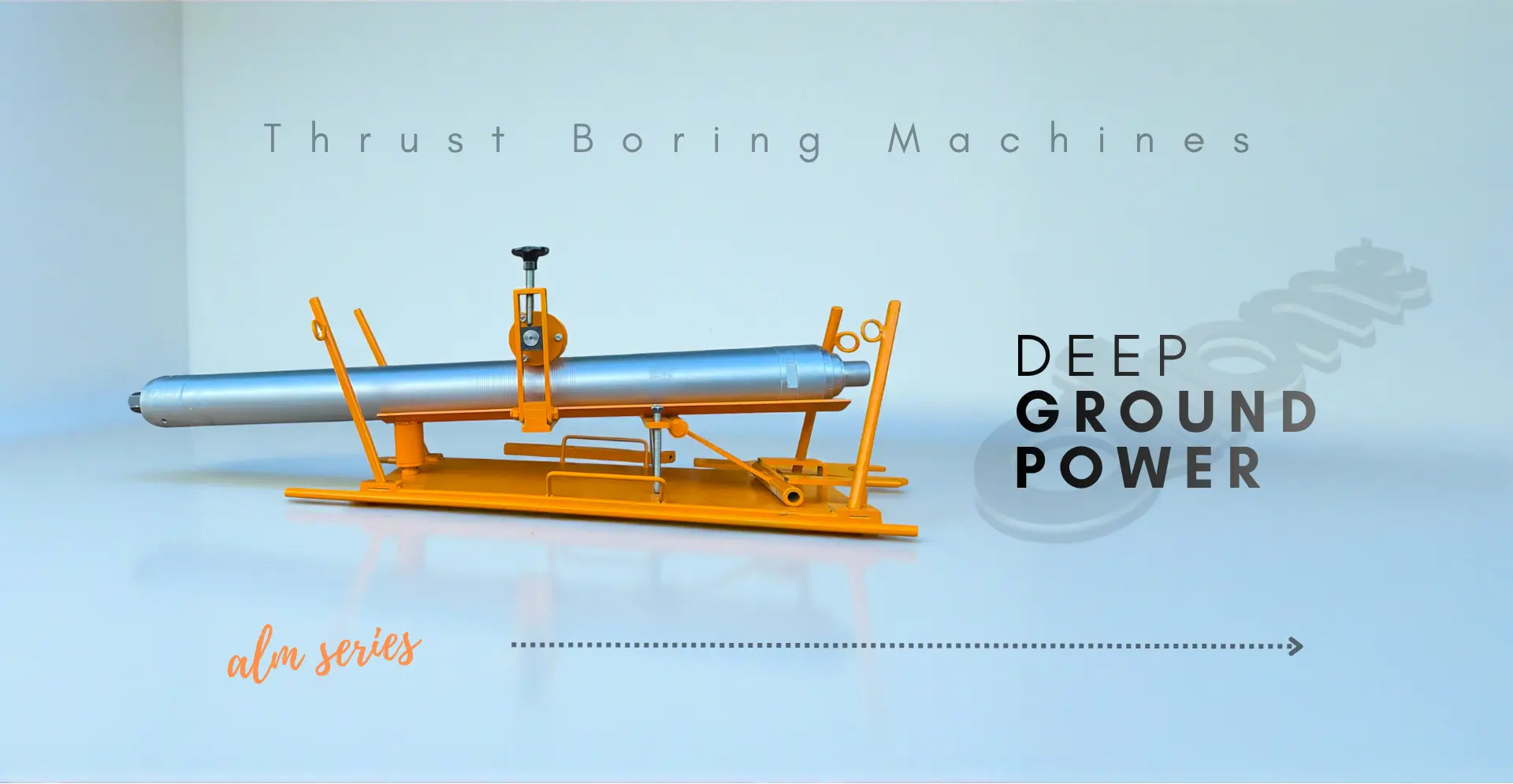

1. Minimum manpower is used in target determination and startup.

2. Depth Determination: The movement axis of the rocket should be in the depth (h) of 12-15 times of the diameter of the rocket.

3. The longer the distance to be bored, more sensitive the target determination is, therefore good observation and precise alignment are essential.

4. Distance to be bored : Distance to be bored depends on the appropriacy of the ground formation, the air temperature and the air pressure applied. In general use, a distance of 100 meters can be performed.

5. Starting plate is placed approximately 40 cm. away from the surface to be bored and is fixed on the ground in the direction of the arrow by means of four ground spikes.

6. Rocket is placed on the starting plate and tightened by means of roller bolt.

7. Target is determined.

8. For forward motion of the rocket the air hose is turned to the right, for backward motion of the rocket the air hose is turned to the left till the end.

9. It must be checked that the air hose is turned to the right while the rocket is on the starting plate. Otherwise, the gear part and the other moving parts of the roller can be damaged.

10. Air feeding valve is opened half until the rocket leaves the plate completely and then the valve is fully opened.

11. Boring speed is 5-10 meters/hour in average in a soil or clay formation when the air pressure is 87 PSI – 6 Bars .

12. To remove the rocket from the bore: The plate is removed, the air feeding valve is closed and the air hose is turned to the left till end. Then, the air feeding valve is opened and the rocket starts moving back.

Why Choose Us

High-Performance Machinery

Our thrust boring machines deliver exceptional power and efficiency, enabling fast and precise underground installations even in the toughest soil conditions.

Innovative Engineering

Each machine is the result of cutting-edge design and continuous R&D, combining modern pneumatic technology with user-focused functionality.

Reliable and Durable

Built with top-grade materials and tested under strict conditions, our machines are engineered to perform consistently and last for years in demanding environments.

Hammer Drill & Down The Hole Hammer Drill

Hammer drill – Down the hole hammer is a pneumatic drilling hammer,

that is used in the operations of mining and bringing out underground water for a boring purpose.

Hammer Drilling – Down the Hole Hammer

Hammer drilling is a piling system wherein a percussive bit is utilized and fitted

to a rotary drilling rig using high-pressure air compressors to drive the hammer whilst drilling. It is one of the most efficient methods to drill through hard rock strata. Down the Hole Hammer

Details: good rock breakage, high penetration rates, high productivity. Optimal hole quality, reliability, and long service life give the best blasting results.

Unmatched in longevity and penetration rates, these performance-driven hammer drill models are able to drill holes from 76,2 to 254mm in diameter.

news

Would you like to contact one of our team over the email? Just submit your details and we’ll be in touch shortly.